UEC has invested substantial resources to be the most automated, agile, flexible and state-of-the-art systems design, engineering and prototyping, production facility in the Southeast region. We have a capitalized investment of over $6 million spanning the last seven years for factory automation, complex surface mount electronics assembly and test equipment, as well as engineering and program management software tools. UEC has a fully integrated Enterprise Resource Planning (ERP) system that facilitates all business systems and performance metric reporting including Earned Value Management (EVM).

Test and Inspection Equipment

- SPEA 4040 Multimode Flying Probe In-Circuit Tester and Optical Acceptance

- Sorensen Electronic DC Load

- Tektronix Oscilloscopes

- HP Signal Generators

- Boonton Power Meter

- Lambda, HP & Protek Power Supplies

- Meiji Stereo Microscope w/Video Camera & X/Y Table

- Full Suite of Electronics Bench Test Equipment

- Rhode & Schwarts FSV 10Hz – 60 GHz Spectrum Analyzer

- Fireberd 8000 Data Test Set

- LabView Software Execution and Programming

- UID Label Verification

- Romer Absolute 3D Measuring/Inspection Arm

- Maccor Series 4000 Automated Battery and Cell Tester

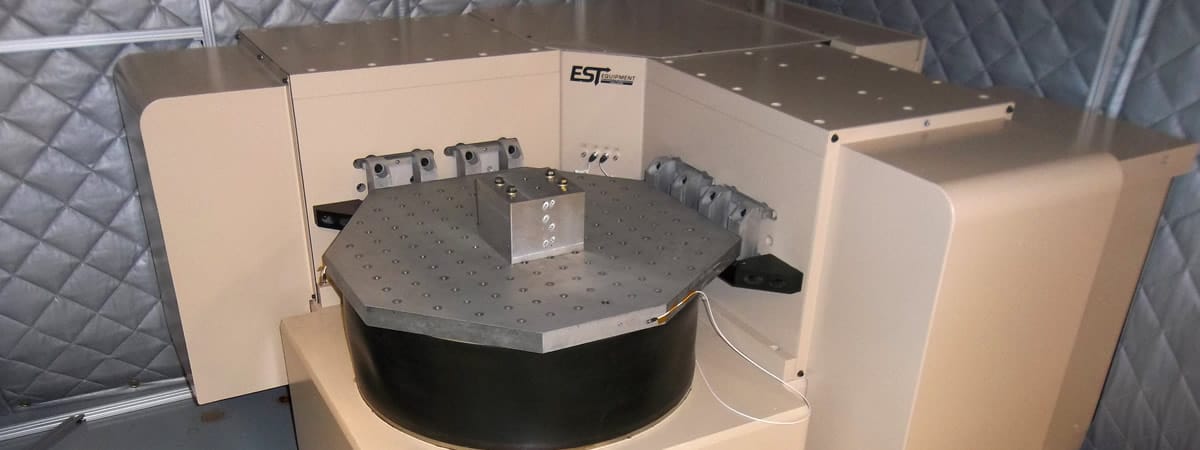

Environmental Stress Screening

- HALT/HASS

- Thermal cycling – Max Temperature Range of +200C to -100C max Change/Ramp Rate of 100C/minute.

- ElectroDynamic (ED) Vibration – Single Axis Random or Sine and Dual Axis Random Vibration.

- ElectroDynamic (ED) Vibration – Frequency Spectrum from 20 to 2000Hz Capable of meeting NAVMAT vibration profiles at ambient temperature.

- Repetitive Shock (RS) Vibration – 3-Axis Random Vibration with 6 Degrees of Freedom with Maximum Acceleration of 75 gRMS.